Vortex Powered Aeration

How It Works

The VorTech Vortex Powered Aeration™ (VPA™) system is powered by vortex (or cyclonic) flow. The patented VPA™ system operates by pumping liquid at a high wire-to-water efficiency from within a tank to the water surface for direct contact with air and oxygen in a cyclone to effect oxygen transfer.

The air and water mixture is then jetted back into the tank where it powerfully mixes the contents of the tank, both vertically and horizontally.

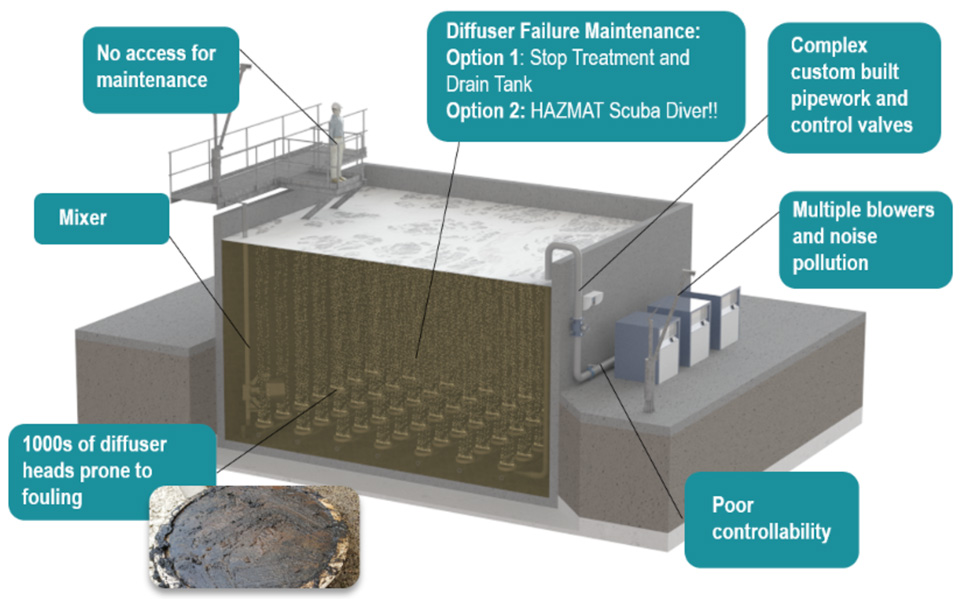

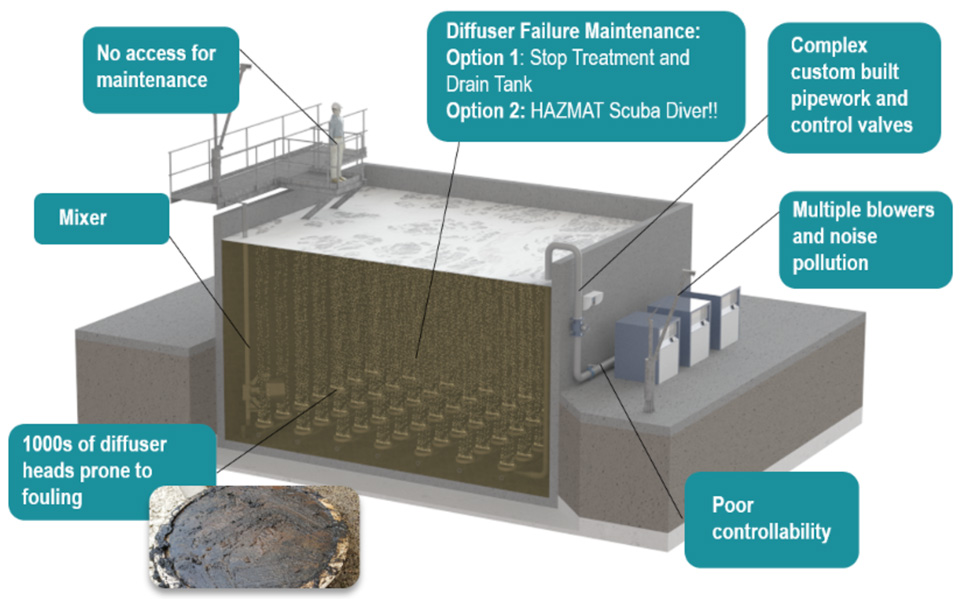

The Problem

Beyond energy inefficiency, existing aeration technologies also suffer a range of pain points such as:

- KSignificant equipment and infrastructure requirements

- KSignificant time for installation

- KPoor retrofitability

- KPrecarious maintainability requirements

- KComplex control protocols

- KNoise pollution

The Problem

Aeration currently accounts for between 50% and 75% of a wastewater treatment plants energy use. This equates to 1.5% – 2.25% (average 1.9%) of a developed country’s electricity equating to about 279 TWh requiring approximately 24 million tonnes of oil equivalent (toe) annually. This typically is due to poor oxygen transfer performance and control.

Beyond energy inefficiency, existing aeration technologies also suffer a range of pain points such as:

- KSignificant equipment and infrastructure requirements

- KSignificant time for installation

- KPoor retrofitability

- KPrecarious maintainability requirements

- KComplex control protocols

- KNoise pollution

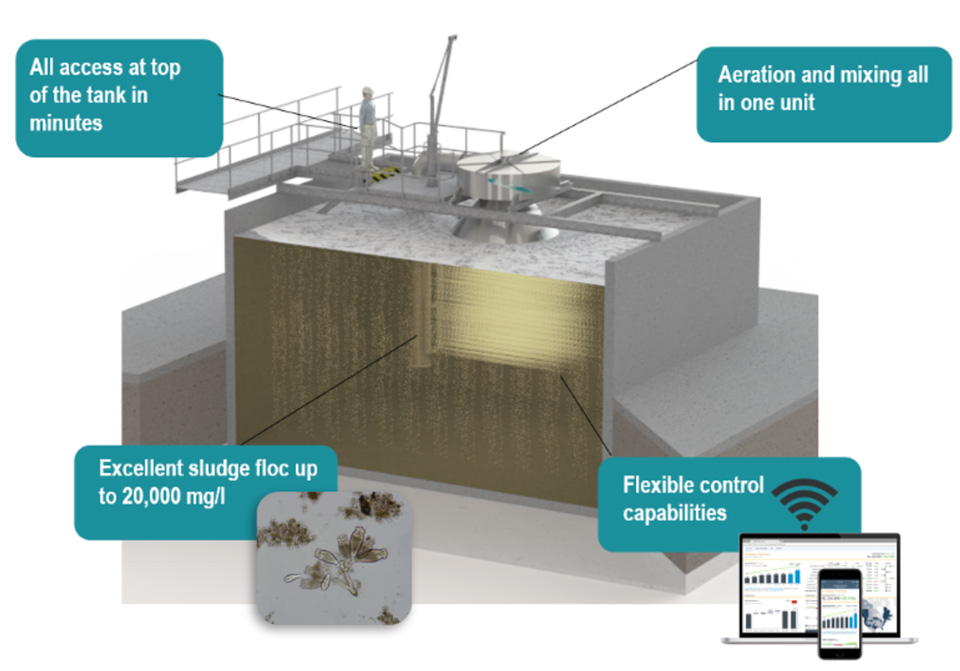

The Solution

The Vortex Powered Aerator™ is a patented technology that replaces all of the above infrastructure with just one unit, which is fully automated for efficient control across a range of treatment processes. The VPA™ can supply more than two times more oxygen per unit of energy consumed and the full system can be dropped in at the top of the tank in a matter of days.

This simple but innovative solution provides the following benefits:

- LLow total cost of ownership (pay back in 3 to 5 years)

- LIcon List Item

- LRetrofit in days instead of months

- LAll access at the top of tank for maintenance in minutes

- LEfficient fully automated control

- LLower noise (20dB less than diffused)