Our Projects

VorTech have successfully delivered its VPA solution to solve challenges on numerous projects covering a wide range of applications including municipal wastewater treatment plants, and industrial (e.g. food and beverage) facilities. We have also delivered our hydraulics and CFD expertise to solve challenges in large scale water infrastructure projects including aeration process upgrades, vortex drop shafts and deep sewers, reservoirs and pumping stations.

Municipal WWTP – UNITED KINGDOM

8 x VPA-S5040 systems were retrofitted to 4 x 60 year old oxidation ditches at a 120,000 PE wastewater treatment plant. The purpose of the upgrade was to reduce total lifecycle costs (energy and maintenance) reduce noise pollution and enhance safety of operations.

VPA Type: VPA-S5040

Location: United Kingdom

Configuration: Oxidation Ditch

Installation type: Retrofit

Wastewater type: Municipal

PE: 120,000

Industrial WWTP – Ireland

2 x VPA-S1010 systems were retrofitted to 2 membrane bioreactors (MBRs) treating industrial waste from carbonated beverage production. The purpose of the upgrade was reduce energy intensity (which resulted from existing diffuser fouling issues) and eliminate

costly and unsafe tank draining processes for maintenance.

VPA type: VPA-S1010

Location: Ireland

Configuration: MBR

Installation type: New build

Wastewater type: Retrofit

PE: 4,000

Municipal WWTP – Ireland

The VPA-S3 system was retrofitted onto the aeration tank at an Irish municipal WWTP. 1 x VPA-S3020 unit was deployed to the WWTP which has a PE of circa 3,333.

VPA Type: VPA-3020

Location: Ireland

Configuration: CMAS

Installation type: Retrofit

Wastewater type: Municipal

PE: 3,333

Industrial WWTP – United Kingdom

The VPA-S6063 system was installed at an abattoir in the UK for aerobic and anoxic treatment at the site’s activated sludge facility. The system was installed as part of a new build.

VPA type: VPA-S5

Location: United Kingdom

Configuration: CMAS

Installation type: New build

Wastewater type: Industrial

PE: 19,000

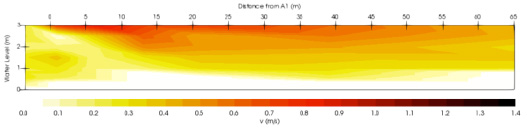

CFD – Oxidation ditch

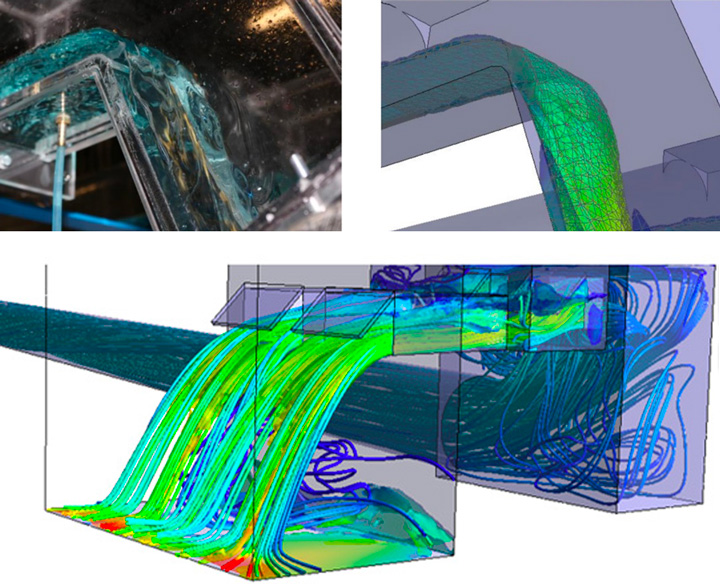

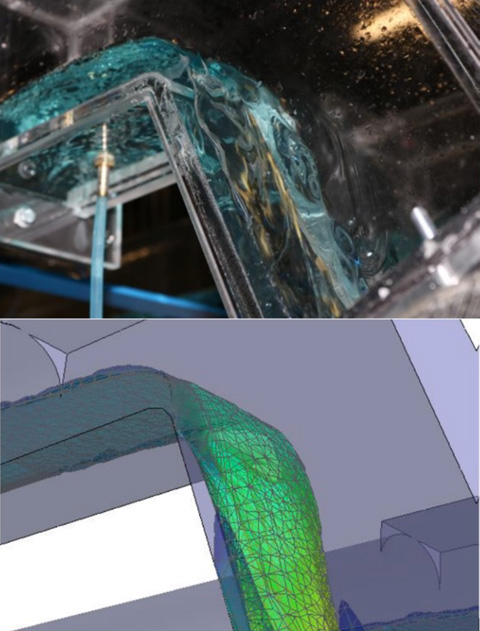

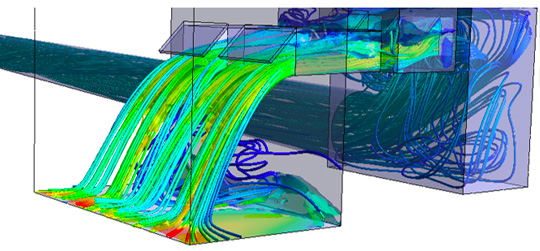

Hybrid Physical and CFD Modelling: CSO intercept structure

Once a physical model has been constructed and compared to the CFD model, the numerical model can then be refined in order to maximise the value and accuracy of the model. This can reduce cost and time that can be required when constructing the physical structure.

Hybrid Physical and CFD Modelling: CSO intercept structure

Once a physical model has been constructed and compared to the CFD model, the numerical model can then be refined in order to maximise the value and accuracy of the model. This can reduce cost and time that can be required when constructing the physical structure.