How Vortex Powered Aeration™ (VPA) can support the dairy industry’s triple bottom line

Dairy processing is hugely water intensive, with even the most efficient plants typically requiring 1-3 litres of water to process a single litre of milk. In addition to milk residues, wastewater volumes are further increased due to cleaning, cooling, and other operational needs.

Aeration typically accounts for 60% of a wastewater treatment plant’s power consumption. The inefficiencies of conventional aeration methods make it challenging to comply with environmental regulations and meet corporate sustainability goals.

BENEFITS OF VPA

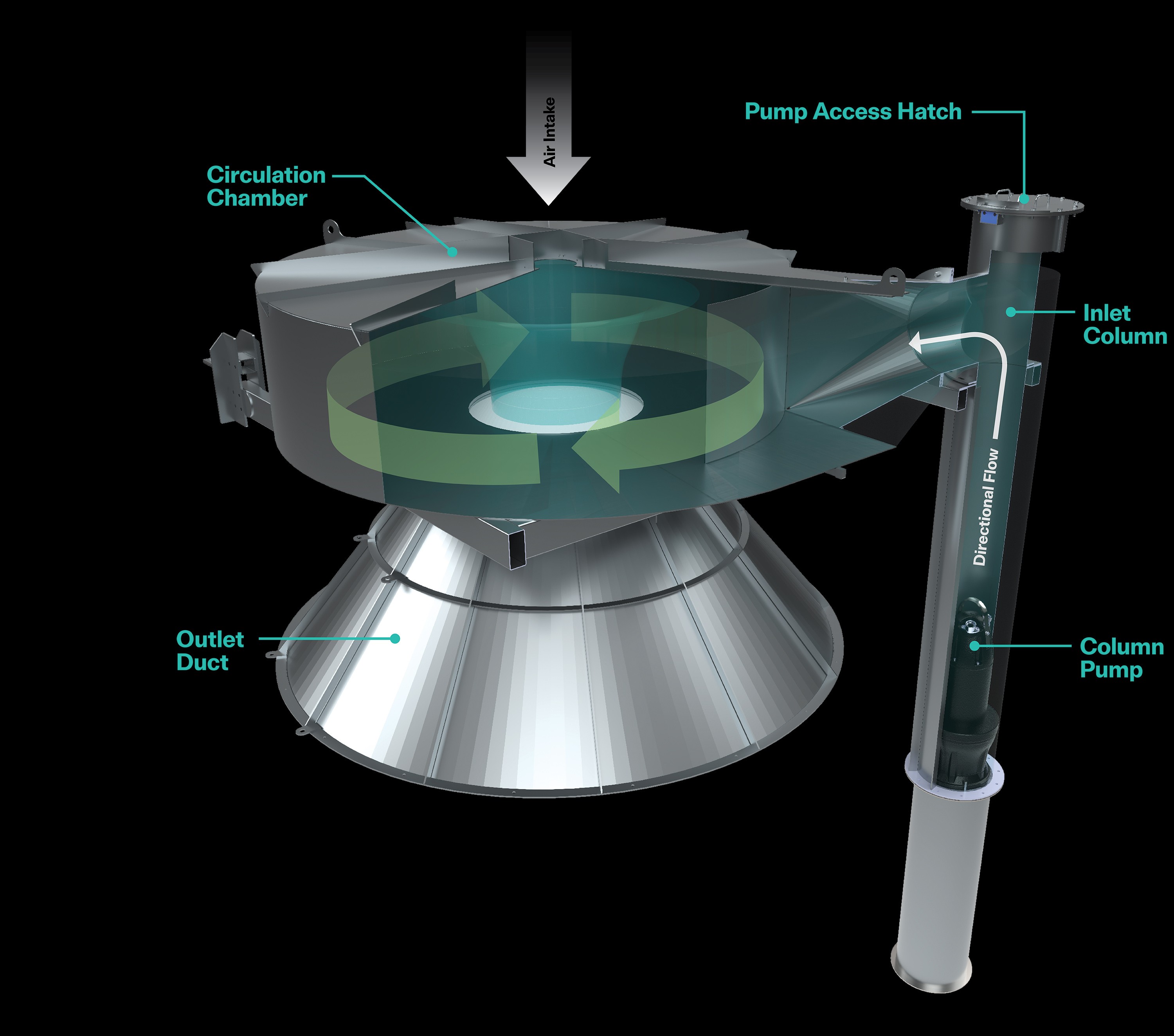

Vortex Powered Aeration™ (VPA™) is a groundbreaking advancement in wastewater treatment, combining efficiency, reliability, and ease of operation to address the limitations of conventional aeration methods.

Rethinking aeration can reduce carbon emissions, improve community relations and working conditions, and cut wastewater treatment costs.

CREAM OF THE CROP

A multi-national dairy products manufacturer has deployed VPA™ technology at their milk powder production facility in Ireland to increase capacity and provide redundancy.

The retrofitted VPA™ solution delivered a 3.8x increase in airflow compared to a conventional aeration system within the same power budget.

Invest to Save: How Vortex Powered Aeration™ can support the dairy industry’s triple bottom line

The mounting costs of aeration for the dairy industry

How Vortex Powered Aeration™ (VPA™) works

Triple bottom line benefits of VPA™

CASE STUDY: Milk powder production facility

DAIRY WWTP

A VPA™ unit was installed in three days in a dairy oxidation ditch to increase aeration capacity with no down time.

VPA Type

VPA-3020

Configuration

Oxidation Ditch

Installation type

Retrofit

Wastewater type

Corporate

Population Equivalent

10,000

HAVE A QUESTION?

If you didn't find the answers you were looking for, please don't hesitate to reach out to us.